We are environmentally responsible across all our operations

We aspire to be Australia’s most respected energy company. That means we place the highest priority on the health and safety of the environment and the communities where we operate. We are committed to continual improvement of our environmental performance, and to reducing any potential impacts of our operations or from our products.

Managing our environmental footprint, improving our energy efficiency and reducing our emissions are all important priorities. Our other focus areas include water and land management, and minimising waste.

Read our Health, Safety, Security & Environment (HSSE) policy.

温室气体排放和能效

Taking action

We are taking action on climate change by working to reduce the emissions intensity of our operations and developing products that are more efficient for our customers. We work closely with the Clean Energy Regulator to report on our emissions at our Geelong Refinery.

Reporting our emissions

每年我们都会监控并向联邦政府监控我们的温室气体(GHG)排放和能源消耗。我们提供的信息通过清洁能源调节器报告系统每年发布。我们的GELONG炼油厂的温室气体排放受到保障机制下清洁能源调节机构的温室气体排放基线调节。

要了解更多信息,请参阅National Greenhouse and Energy Reportingand保障机制。

提高我们的能源效率

Producing the same amount using less energy is what the energy efficiency challenge is all about. In addition to reducing greenhouse gas emissions, energy efficiency makes good business sense.

We are committed to investing in projects that will help us minimise our energy use. At our Pinkenba terminal in Brisbane, we’ve recently converted 284 lights to LED, resulting in a 64 percent energy saving and a reduction of 272 tonnes of GHG emissions each year. You canread the full story here.

在我们的吉朗炼油厂,能源使用代表了我们经营成本的近30%,这使得能源效率成为最优先事项。

One of our energy projects has established and verified key energy indicators, so that our operations team knows how much energy is being used across the refinery. Much like the dashboard in your car, these indicators provide the information needed to make energy-efficient choices in operating the refinery’s equipment. We achieved two percent energy reduction in the first year, and we expect further reductions.

空气质量

保护我们的空气

Australia has some of the best air quality in the world. Manufacturing, storing, supplying and using fuels and other oil products can cause air emissions. We are committed to protecting our air quality by managing emissions from our operations and delivering high-performance products to reduce our energy consumption and emissions.

我们仔细监控我们的排放,计划改进,并尽量减少任何环境影响的风险,我们定期向适当的当局报告。

成功减少了空气排放

To reduce air emissions associated with our operations and to meet our regulatory requirements, we have made significant investments in our equipment and processes.

Reducing VOCs

雷电竞Viva Energy已经投入了超过1300万美元的1300万美元,减少了我们在吉朗炼油厂和澳大利亚各大燃料终端的汽油散装储罐中的挥发性有机化合物(VOC)排放量。这涉及在我们的燃料箱中安装内部浮动盖子;这些盖子坐在燃料的顶部并提供紧密的密封,使得排放的逸出是最小化的。

监测发现,在10年内,我们的Gelong炼油厂的汽油储罐碳氢化合物排放量减少了86%以上。

Vapour Recovery Units (VRU) are installed at our major fuel terminals and at a select number of service stations to collect vapour emissions during car and tanker refuelling operations. Filters are used to capture the vapours, which are then converted to liquid, turning a potential air emission back into fuel. This closed system significantly reduces the amount of VOC emissions that may escape to the air.

报告我们的表现

我们收集我们的空气排放数据,以便我们设定目标并遵守我们的监管义务。我们致力于每年向我们设施的排放量报告绩效数据。我们的数据公开提供给社区,行业和政府。

要了解更多信息,请参阅the国家污染物库存。

提供能量

我们致力于更有效地提供能源,以帮助满足澳大利亚人的不断增长的能源需求。

2004年,我们委托澳大利亚的第一个超低硫磺柴油生产设施。1.6亿美元的投资有助于使用柴油减少车辆,卡车和设备的硫排放。

As the exclusive Shell licensee in Australia, we have access to Shell’s range of high-quality products across both fuels and lubricants. These products are designed to help improve fuel economy – helping motorists improve efficiency and save on energy use.

We employ a team of fuel and lubricant engineers who provide support across a range of industries. The technical support and advice we offer has helped many of our customers improve their energy efficiency. You can read one of our success stories这里。

Learn more about our fuels and lubricants.

水management

保护宝贵的资源

水is an essential resource and we understand that we need to manage our consumption responsibly. Our aim is to minimise water use throughout our entire production and operations chain. We’re always looking for opportunities to improve our water management wherever operational, regulatory and business conditions allow.

水recycling

在我们的Geelong炼油厂,我们需要大量的水来生产加热原油的蒸汽,并在制造时冷却燃料。我们可以保存或回收的每一滴都可能对当地社区进行更多意义。

Roughly 90 percent of the water used at the Geelong Refinery is recycled water from the Northern Water Plant, saving 1.5 billion litres of drinking water each year – or the equivalent of the amount of water used by 10,000 homes per year. The plant was a joint venture between the Geelong Refinery, State and Federal Governments and Barwon Water. It took ten years to complete and cost over $100 million.

Learn more about the Northern Water Plant.

保护我们的环境

Most of our larger facilities are located along the Australian coastline, sometimes within areas of environmental significance. We have the right equipment as well as established internal compliance systems to prevent pollution from water that is discharged from our facilities, as well as regulatory controls through licensing and permits. We use a variety of design principles and water treatment systems at our facilities and retail network to ensure that any impacts of storm water and wastewater on the environment are minimised.

The Kangaroo Wetlands adjacent to our Newport terminal have played an important role in improving environmental quality and visual aesthetics in the local community. The wetlands provide sediment filtration and biodegradation of storm water runoff from the terminal as a final water treatment stage prior to release into the Yarra River and Port Phillip Bay. A study completed by Monash University on the performance and water quality of the Kangaroo Wetlands found storm water discharged is of a quality higher than general storm water runoff from urban areas.

Learn more about Kangaroo wetlands.

浪费和回收

Minimising waste

We try extremely hard to eliminate, reduce, reuse or recycle our waste across all of our operations and the projects we undertake.

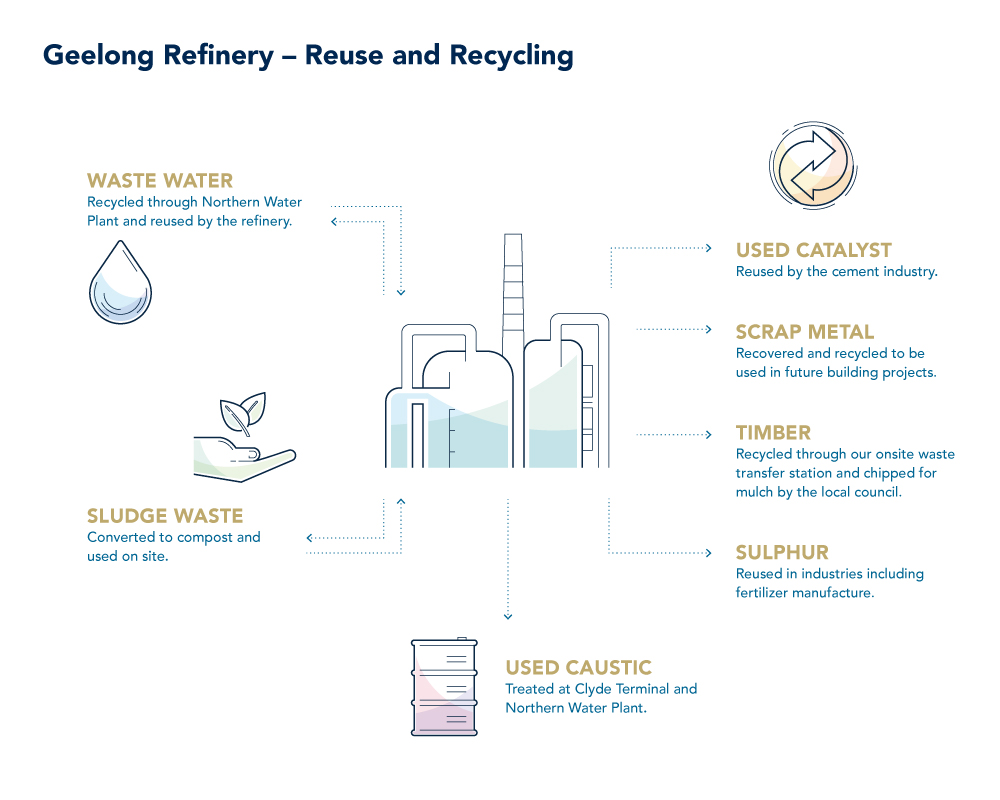

We don’t waste opportunities

Waste management practices at our Geelong Refinery really are world-class:

- 100 percent of all wastewater is sent to the Northern Water Plant for recycling.

- 90 percent of the water used in refinery processes is recycled water from the Northern Water Plant.

- About 1,300 tonnes of waste catalyst are sent to the cement industry for reuse each year, diverting it from landfill.

- Sulphur waste is reused by industries such as fertiliser manufacturing.

- Spent caustic is sent to our Clyde terminal, where it is neutralised in our water treatment plant.

- Hydrocarbon sludge waste is treated and processed by mixing it with mulch and biodegrading it into compost. The compost is then used in the land surrounding the refinery, which is why the 100,000 native trees that we’ve planted over the years look so healthy.

- 其他废料包括钢,土壤和木材,通过我们现场的废物转移站回收。

Learn more about our waste management.

At theClyde Terminal Conversion Project专门的废物管理团队确保了38,000吨的废金属,30,000吨的高档沙子正在悉尼建设项目中重复使用。

可持续包装

Because we sell products that need packaging, we’ve been working with the Australian Packaging Covenant (APC) to reduce the impact of our packaging on the environment. We fully support the principles and are a signatory of the APC. Each year we submit an annual report on our activities and our progress.

查看我们的APC 2018报告(PDF1.6MB.)

土地管理

目标零

我们绝对致力于追求对人们造成伤害并保护环境的目标。我们称这个目标为零。

我们必须尽我们所能,以尽量减少对土壤和地下水质量的任何影响,因为我们的任何设施都泄漏或泄漏。我们还在任何历史问题上监控和与监管机构合作,包括遗留和运营网站的补救。

No product to ground

The principle of ‘no product to ground’ describes one of our environmental commitments to Goal Zero. We are committed to investing in processes and equipment that are safer, more reliable and more efficient, and using monitoring and control systems to rapidly detect problems – especially leaks.

为我们吉朗炼油厂和其他主要设施s, we continue to invest in leak detection technology such as EMAT (Electromagnetic Acoustic Transducer), a real-time advanced pipework inspection technique. We also continue to implement advanced leak detection technology across our retail service station network.

Land for the future

We have a dedicated team that manages environmental assessments and remediation, working with property owners, local communities and regulators to ensure land is suitable for our ongoing operations or future development. We support sustainable approaches to remediation that consider the interests of our various stakeholders.

我们的Clyde终端转换项目很好,以将前炼油厂转换为世界级的导入和存储终端。了解有关Clyde终端转换项目的更多信息这里。

我们在与我们的Geelong炼油厂相邻的前门区实施了景观管理计划。与吉朗市等利益攸关方合作,环境部门,主要产业和Corangamite集水区管理局,我们投资超过700,000美元来管理历史影响,以原生植被,重新制定前山脉。

噪音和气味

成为一个好邻居

我们承认机械,泵,现场车辆,耀斑和警报器的噪音和异味可能是我们邻国和当地社区的关注。我们致力于最大限度地减少我们在我们运营的社区的任何影响。

We have a number of processes and controls in place across our facilities to ensure our operations don’t cause noise issues. As an example, to help us mitigate noise from our Gore Bay facility, we have:

- A rigorous ship selection and vetting process based on noise performance.

- 我们在周末以后开始驳船运营的过程。

- 在某些设备周围安装了声学外壳。

- 如果他们导致社区任何问题,船上的泵送率降低。

来自一些产品的气味可以是由硫化合物,氮化合物和烃引起的,并且可以作为储存原油和燃料油以及沥青生产而产生的。我们致力于最大限度地减少气味:

- Use of a Vapour Emission Control System (VECS) at Gore Bay.

- 更换燃料油箱上的密封件,以防止异味逃逸。

- Testing fuel oil samples for odour prior to delivery.

- Planning our projects better to neutralise any potential odours.

- 积极回应投诉并监测我们的空气排放。

我们的主要设施

The Geelong Refinery

我们为过去十年的炼油厂的环境成就感到自豪,其中包括数亿美元的环境改善和举措的投资。

耀斑是炼油厂最明显的部分之一,往往是社区感兴趣的。常用于世界各地的炼油厂,耀斑充当压力安全浮雕装置。要了解更多关于耀斑在炼油厂的角色,请阅读我们的Flare Fact Sheet.

环境许可证

吉朗炼油厂在环境保护局维多利亚(EPAV)发布的环境许可证下运作。许可证包含与废物处理和处理,空气和排水,以及噪音和气味有关的一系列严格条件。

炼油厂需要监督和报告遵守这些条件。结果通过一个结果提交给epav年度绩效声明。To ensure that the EPAV is aware of any potential impacts, and that there is an appropriate response, reporting of non-compliances is a condition of our environmental licence.

为了展示我们与EPAV和当地社区的开放和透明的方法,我们发布了一张列出我们的环境监测和符合的表,以及任何许可证违规行为,并定期更新。

2018-20环境问题

空气

Recycling

水

| 日期 |

Activity |

Description |

Outcome |

4 October

2020.

|

Neighbouring property impacted by noise |

During preparation for maintenance on a refinery unit, an activity using steam caused noise to be detected outside of the refinery boundary.

|

EPA已通知。The rate of steaming was reduced to control the noise level. The protocol around the use of steam has been changed to prevent the issue in future. |

2 October

2020.

|

Contaminated discharge water |

During preparation to bring a refinery unit back on line, some water containing rust was discharged from one of the refinery outfalls. |

该事件报告给EPA。活动停止了。

|

9月13日和17日

2020.

|

Product leaked from a pipe on the jetty |

在船舶中加载少量产品从码头上的管道泄漏 |

该事件报告给EPA。受影响的法兰被修复。 |

7月19日

2020.

|

Hydrocarbon was observed at one of the outfalls |

由于7月14日泄漏而溢出的碳氢化合物通过许可的出口之一排出。

|

EPA已通知。安装吸收臂被安装以捕获并除去排出的产品。

|

14 July

2020.

|

Product leaked from a pipe

|

在船舶装载产品期间,从管道撞击土壤泄漏。

|

该事件报告给EPA。The affected section of the pipe was replaced and the area of the spill cleaned up.

|

16March

2020. |

站点宽SO2排放量高于许可证限额 |

在操作变化期间,炼油厂的单位变得不稳定,导致堆叠硫极限被超出。对社区没有影响。除了炼油厂边界之外没有检测到硫磺。 |

该事件报告给EPA。The unit returned to normal operations within the hour. |

19二月

2020. |

站点宽SO2排放量高于许可证限额 |

An incident on a refinery unit required a safety response that resulted in the sulphur limit being exceeded. |

该事件报告给EPA。该单位稳定,继续维护活动。 |

13二月

2020. |

站点宽SO2排放量高于许可证限额

|

在计划的维护过程中,超出了炼油厂边界之外检测到气味

|

通过称为第30A部分的过程提前通知EPA,并在维护工作期间批准临时增加的排放。对EPA报告了这种具体的超标。

|

14 F.ebruary

2020.

|

污染的雨水

|

继炼油厂旁边的雨水排出区附近观察到大雨之后,在炼油厂旁边的雨水排出部分附近观察到碳氢化合物。对野生动物或环境没有影响。

|

该事件报告给EPA。

|

4 February

2020.

|

冷却水中的沉积物超过许可限制

|

Windy and rough conditions resulted in turbid water. During routine sampling, total suspended solids (15mg/L) in water exiting the refinery was higher than the licence limit.

|

该事件报告给EPA。

|

231月2020年1月

|

污染的雨水

|

继炼油厂旁边的雨水排出区附近观察到大雨之后,在炼油厂旁边的雨水排出部分附近观察到碳氢化合物。对野生动物或环境没有影响。

|

该事件报告给EPA。

|

1月14日和23日2020年1月23日

|

站点宽SO2排放量高于许可证限额

|

在计划维护工作期间,炼油厂的单位变得不稳定,导致超出堆叠硫极限。对社区没有影响。

|

The EPA was notified in advance through a process known as a Section 30A and approved the potential for increased sulphur emissions during the maintenance works. These specific exceedances were reported to the EPA.

|

2019年12月31日

|

Q4水测试结果

|

832 water outfall tests conducted on water discharged from the refinery.

|

99% of water tests within licence limits.

|

19December 2019

|

SO2排放量高于DP25的许可限额

|

在操作变化期间,炼油厂的单位变得不稳定,导致堆叠硫极限被超出。对社区没有影响。除了炼油厂边界之外没有检测到硫磺。

|

该事件报告给EPA。The unit returned to normal operations within the hour.

|

5.December 2019

|

SO2排放量高于DP25的许可限额

|

A unit at the refinery became unstable resulting in the stack sulphur limit being exceeded. There was no impact on the community.

|

EPA报告了超越。The unit was returned to normal operations.

|

11月29日

2019年

|

从炼油厂堆叠中观察到可见排放

|

在重启炼油机组期间,从其中一个炼油厂堆叠中观察到可见的烟雾。

|

The EPA was notified in advance through a process known as a Section 30A and approved the potential for visible emissions during the maintenance works. This specific exceedance was reported to the EPA.

|

12 October 2019

|

来自炼油厂码头的轻微漏油

|

在进行炼油厂码头的常规工作时,少量油被释放到Corio海湾。

|

该事件报告给EPA并在可行的范围内完成清理。

|

23 September 2019

|

SO2 DP25(SRU堆栈)的排放量高于许可证限制

|

A unit at the refinery became unstable resulting in the stack sulphur limit being exceeded. There was no impact on the community.

|

该事件报告给EPA。The unit was returned to normal operations.

|

5.2019年8月

|

邻近财产报告了H2S气味

|

在计划的维护过程中,超出了炼油厂边界之外检测到气味。

|

通过称为第30A部分的过程预先通知EPA,并在维护工作期间批准了气味的可能性。对EPA报告了这种具体的超标。

|

2019年8月4日

|

A neighbouring property reported noise beyond the refinery boundary.

|

燃烧速率高于正常速率,导致炼油厂边界之外检测到噪音。

|

The EPA were notified in advance of the potential for noise beyond the refinery boundary. This specific exceedance was reported to the EPA.

|

2019年7月19日

|

少量从跳线管道上滴下阀门的碳氢化合物 |

在进行炼油厂码头的常规工作时,少量油被释放到Corio海湾。 |

该事件报告给EPA并在可行的范围内完成清理。 |

| 30 June to 11 August 2019 |

Sulphur dioxide emissions exceeding licence limits occurred over several days |

在计划维护工作期间,炼油厂的单位变得不稳定,导致堆叠硫极限被超出多次超出。对社区没有影响,在炼油厂的边界之外没有检测到二氧化硫。 |

通过称为第30A部分的过程提前通知EPA,并在维护工作期间批准临时增加的排放。These specific exceedances were reported to the EPA. |

| 2019年6月23日 |

令人反感的气味从炼油厂堆栈中排出

|

由于维护工作在吉朗炼油厂的两名硫磺恢复单位上进行,社区的一些成员在6月23日的周日经历了气味。

|

通过称为第30A部分的过程提前通知EPA,并在维护工作期间批准临时增加的排放。在6月23日星期日建议EPA,社区成员因气味而报告影响。事件正在调查。报告受到影响的社区成员通过吉朗炼油厂直接联系。

|

| 2019年5月31日 |

超出许可限制的二氧化硫排放

|

During planned maintenance work, a unit at the refinery became unstable resulting in the stack sulphur limit being exceeded. There was no impact on the community.

|

通过称为第30A部分的过程提前通知EPA,并在维护工作期间批准临时增加的排放。对EPA报告了具体的超标。

|

| 17 May 2019 |

超出许可限制的二氧化硫排放 |

During maintenance work, a unit at the refinery became unstable resulting in the stack sulphur limit being exceeded. There was no impact on the community. |

EPA报告了超越。

|

| 4月5日,16日和23日 |

Sulphur dioxide emissions intermittently exceeded licence limits on three dates in April |

During planned maintenance work, a unit at the refinery became unstable on three separate occasions resulting in the stack sulphur limit being briefly exceeded on each date. There was no impact on the community. |

Maintenance work was completed under the Section 30A granted by the EPA. The exceedances were reported to the EPA.

|

| 30 March 2019 |

来自炼油厂码头的轻微漏油 |

在进行炼油厂码头的常规工作时,少量油被释放到Corio海湾。 |

该事件报告给EPA并在可行的范围内完成清理。 |

| 2019年3月28日,29日和30日 |

超出许可证限制的二氧化硫排放在连续三天发生 |

在维护工作期间,炼油厂的单位在连续三天中变得不稳定,导致每次日期短暂超过堆栈硫磺限制。对社区没有影响。 |

将这些事件报告给EPA,申请30A部分,因此可以进行进一步的维护。 |

| 2 March 2019 |

Discharge of material from the refinery flare |

在炼油厂的单位重新开始期间,该单元变得不稳定。过程安全机构激活,导致从影响邻近财产的耀斑释放材料。 |

EPA和炼油厂邻居被通知。 A clean-up of the impacted property was undertaken in conjunction with the EPA and the neighbouring business. 正在进行对事件进行调查。 |

| 2019年1月25日 |

Temperature of refinery cooling water exceeded licence limit |

The maximum temperature recorded by the Bureau of Meteorology in Geelong on 25 January 2019 was 43.9 degrees celsius. Routine sampling of the temperature of the water exiting the refinery on this date was recorded at 37 degrees, exceeding the license limit of 35 degrees. |

该事件报告给EPA,并进行调查。随后的测试表明,炼油厂的冷却水温已恢复到正常水平。 |

| 2019年1月5日 |

超出许可限制的二氧化硫排放 |

在计划维护工作期间,炼油厂的单位变得不稳定,导致堆栈的硫磺极限超出。对社区没有影响。 |

该事件报告给EPA。该单位稳定,继续维护活动。 |

了解有关我们吉朗炼油厂的更多信息,在我们的网站上阅读。

纽波特终端

我方新港码头条件设置out in a licence issued by the Environment Protection Authority of Victoria (EPAV). Our licence requires a variety of monitoring systems, which provide data that we report annually to the EPAV.

Learn more about Newport Terminal in the Community

了解有关我们纽波特终端的更多信息。

Clyde and Parramatta terminals

The operations of our Clyde and Parramatta terminals are subject to conditions set out in the Environment Protection Licence (EPL 570) and Environment Protection Licence (EPL 660) issued by the NSW Environment Protection Authority (NSW EPA), under section 55 of the Protection of the Environment Operations Act 1997 (POEO Act). We report any issues and how we responded to the NSW EPA.

环境保护许可证可用NSW EPA网站(EPL 570)andNSW EPA网站(EPL 660)。

Under these EPLs, we are required to collect and publically report monitoring data.

The data in this section of our website is provided in accordance with the Protection of the Environment Operations Act 1997 (POEO Act), section 66(6).

Clyde Terminal Environment Monitoring Data

EPL描述了克莱德终端的各种监测点。

Parramatta终端环境监测数据

The EPL describes monitoring points across Parramatta Terminal.

了解有关社区中克莱德和Parramatta码头的更多信息

戈尔湾

The operations of our Gore Bay terminal are subject to the conditions set out in the Environment Protection Licence (EPL 661) issued by the NSW Environment Protection Authority (EPA) under section 55 of the Protection of the Environment Operations Act 1997 (POEO Act).

环境保护许可证可用NSW EPA website.

Under this EPL, we are required to collect and publicly report monitoring data.

我们网站本部分的数据根据“1997(Poeo ACT)第66(6)条”的“环境运营法”的保护提供。

EPL介绍遍布戈尔湾码头的各种监测点:

可以下载这些监视点的数据:

了解有关社区戈尔湾码头的更多信息

应急准备

维护安全可靠的操作对于我们业务的成功至关重要,但我们也谨慎计划如果出现问题,我们可以快速行事。

All of our sites have comprehensive emergency response plans. These involve documenting procedures, staff training, maintaining a major hazards facility safety case where required, and conducting regular emergency exercises involving essential services, local councils, port authorities and other oil companies (where required).

污染事件响应管理计划

在新的南威尔士州,保护环境运营法案1997年(Poeo法案)和保护环境运营(一般)修正案(污染事件响应管理计划)规定,2012规定要求制定污染事件响应管理计划(PIRMP)。

有关POEO ACT和PIMMP的更多信息NSW EPA website.The objectives of these plans are to:

- Ensure comprehensive and timely communication about a pollution incident to Viva Energy employees at either Gore Bay Terminal, Clyde Terminal and Parramatta Terminal, the Environment Protection Authority (EPA), other relevant authorities specified in the Act (such as local councils, NSW Ministry of Health, WorkCover NSW, and Fire and Rescue NSW) and people outside the facility who may be affected by the impacts of the pollution incident.

- 减少和控制污染incid的风险ent at the facility, by requiring identification of risks and the development of planned actions to minimise and manage those risks.

- 减少和控制污染incid的风险ent at the facility, by requiring identification of risks and the development of planned actions to minimise and manage those risks.

The PIRMP for the Gore Bay, Clyde and Parramatta terminals can be downloaded below:

下载戈尔湾污染事件响应管理计划(PDF1.6MB.)

Download the Clyde Terminal Pollution Incident Response Management Plan(PDF216.1KB)

下载Parramatta终端污染事件响应管理计划(PDF147.9KB)

可持续社区

Supporting our local community

We are committed to giving back to the local communities where we live and work.

We are investing in community projects that support mental health, Indigenous participation and substance misuse. We rely on our people, our business practices and our community connections to make this happen.

点击此处了解有关我们社区计划的更多信息。雷竞技好吗